Fiberfrax Durablanket® S | Ceramic Fiber Mats

The Fiberfrax Durablanket product group stands for needled lightweight mats made of ceramic Fiberfrax fibers and effective solutions for a wide range of thermal insulation applications.

- Thickness (mm)

- 13mm 19mm 25mm 38mm 50mm

- Density / volume weight (kg / m³)

- 64 kg / m³, 96 kg / m³, 128 kg / m³, 60 kg / m³

-

Strength

Excellent handling / processing strength.

Heat resistance

Resistance to temperature changes & resistance to chemicals.

Thermal conductivity

Low thermal conductivity & heat storage.

PRODUCT TYPE

Mats (blankets) made of high temperature wool are needled light mats of ceramic (ASW/RCF) High Temperature Wool (HTW) and provide an effective solution for a wide range of thermal insulation applications. They are characterised by excellent insulating properties, high resistance to chemicals, elasticity and dimensional stability. They are exclusively inorganic and therefore do not generate smoke or fumes when exposed to heat. They are available in a wide range of densities and thickness combinations, making them one of the most versatile product groups on the market.

MATERIAL

High temperature wool made of ceramic fibers, also known as ASW (aluminum silicate wool) or RCF (Refractory Ceramic Fiber), have been used for years as the standard fiber type for insulation solutions up to 1250 ° C. Consisting of a mix of aluminum oxide (Al2O3) and silica (SiO 2)2), the fibers offer not only high temperature resistance but also good chemical and mechanical properties.

UNIFRAX®

Unifrax® is one of the world's leading manufacturers of high-performance specialty fibers and inorganic materials that are used in industry, the automotive sector and fire protection. Our goals, philosophy and values build on our efforts to manufacture high quality products that help our customers save energy, reduce pollution and improve fire protection.

Product variations

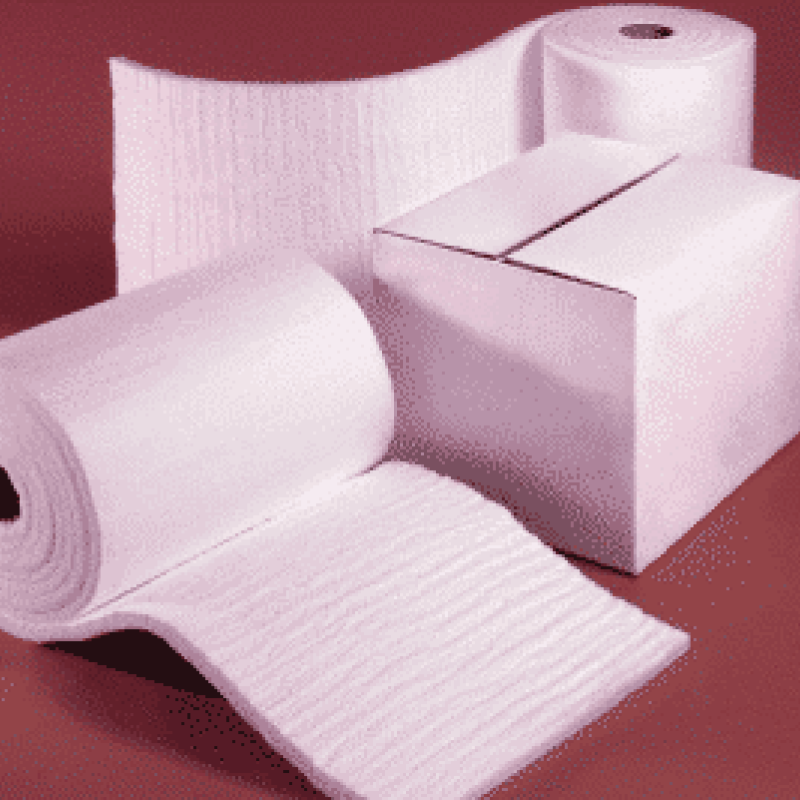

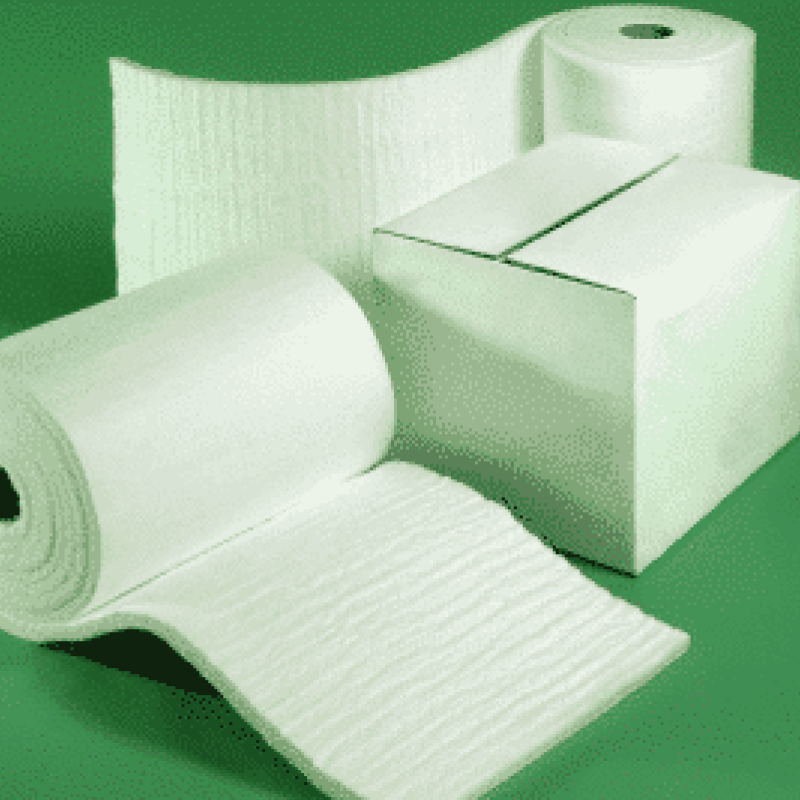

Roll goods

Fiber mats are sold as roll goods as standard. The roll length depends on the selected thickness. As a standard width, we have 610mm wide rolls from stock. Double widths are available on request.

More

Moldings

We manufacture molded parts according to your specifications. The roll goods are made using

Water jet

Punching

Plotting

brought into the right shape for you.

More

Fiber modules

We manufacture fiber modules according to customer specifications that are designed for the insulation requirements of industrial ovens, kilns and heating devices.

MoreTECHNICAL DETAILS

Chemical Analysis

SiO2: 53,0 – 58,0 Al2O3: 4,0 – 47,0 Alkalis: <0,25 Fe2O3: <0,2 Physical Properties Colour: White Classification temperature (° C): * 1250 Melting point (° C): 1760 Mean fiber diameter (My): 3,25 Specific heat at 1000 ° C (J / kgK): 1140 Permanent linear shrinkage (%) after 24 hours 1250 °C: 2,6 Volume weight (kg / m³) 64 96 128 160 Thermal conductivity (W / mK) Average temperature 0,18 0,14 0,12 0,11 800°C 0,27 0,22 0,18 0,16 1000°C 0,42 0,36 0,28 0,21 Tensile strength (kPa) 35 55 75 95 CHARACTERISTICS

The Fiberfrax Durablanket product group stands for needled lightweight mats made of ceramic Fiberfrax fibers and effective solutions for a wide range of thermal insulation applications. Fiberfrax Durablanket products are characterized by excellent insulating properties, high resistance to chemicals, elasticity and dimensional stability. They are exclusively inorganic and thus achieve their dimensional stability, elasticity and thermal insulation properties in many areas of application without the occurrence of smoke or vapors. They are available in a large number of density and thickness combinations and thus represent one of the most versatile product groups on the market.

APPLICATION

- High temperature resistance

- Low thermal conductivity & heat storage

- High tensile strength & elasticity

- Thermal shock resistance & durability

to chemicals - Good sound absorption

-

RBS Kompensator GmbH

In 2009, at the request of many customers, RBS Kompensator GmbH was founded as the 100% sister company of KS Kneissl & Senn Technologie GmbH under Senn Beteiligungs GmbH.

Building on the existing know-how about temperature-resistant high-performance fabrics, these began to be manufactured as individual pieces in the form of soft-material compensators by hand in Erl. Gradually, various sewing and welding machines were acquired in order to be able to produce all common shapes (round / square / round on square etc.) in the best possible way.

Together with our team we try to live the idea of the "One Stop Shop" and make sometimes impossible things possible according to our motto: "Viribus unitis - with united forces".